Model No.︰GM2000

Brand Name︰Gaodetec

Country of Origin︰China

Unit Price︰-

Minimum Order︰1 SET

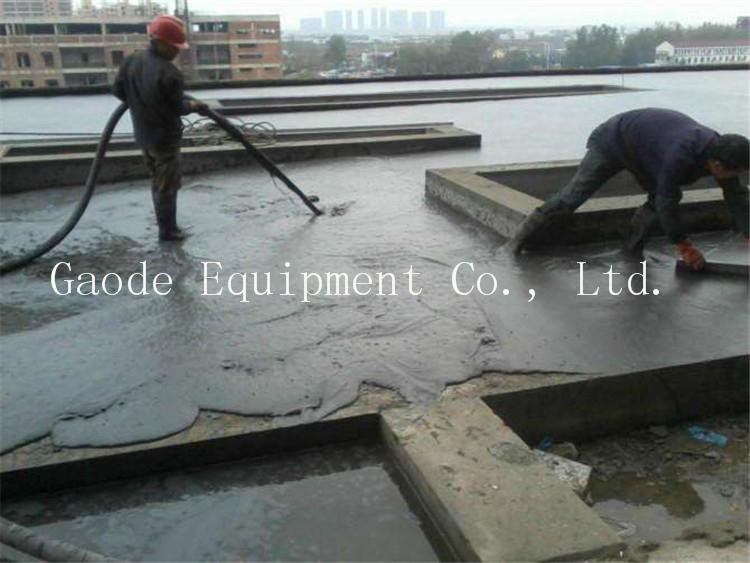

Manual CLC blocks production line

CLC is cellular light weight concrete, has been used in over 40 countries over the past year for build houses, apartments, schools, hospitals, industrial buildings etc.

New building material foam concrete block featurs:

*Low Cost *Light Weight

*Heat Preservation *Sound Insulation

*Fireproofing *Aseismatic

*High Construction Speed *Environmental Protection

Main machines for making CLC blocks include: GM2000 foam concrete mixer, GH76/65/GH50 foam concrete pump, manual molds.

GM2000 foam concrete mixer

The foam concrete mixer mainly includes mixer, feeder hopper, foam generator, water pump, control panel, tank.

Features:

1. It could mixing variable materials, such as cement, fly ash, sand pulp, sand stone, perlite, and slag etc.

2. Specially mixing blades, mixing the material toughly, storage in its bottom is less than 10mm, no material left on the four walls internal the mixing drum.

3. Variable speed mixing and internal structure alteration make its installation easy and mixing frequency high, it saves energy.

Main technical data sheet:

| Model | GM2000 |

| Production Capacity | 15-20 m3/h |

| Output Volume | 1500 L |

| Material Input Volume | 2000 L |

| Main Shaft Revolution | 32 r/min |

| Hopper Lifting speed | 22 m/min |

| Mixing Motor | 11 kW |

| Winding Motor | 5.5 kW |

| Water Pump Motor | 1.1 kW |

| Vibrating Motor | 0.55 kW |

| Foaming System | 5.5 kW |

| Max. Moving Speed | 15 km/h |

| Total Weight | 3200 kg |

| Overall Dimension | 2600x2250x3000 mm |

| GH76/65/50 foam concrete pump for option |

Features:

|

Model |

GH76 |

GH65 |

GH50 |

|

Output |

20m3/h |

10-15 m3/h |

8-10 m3/h |

|

Max. theoretical conveying pressure |

1.5MPa |

1.5Mpa |

1.5Mpa |

|

Hose ID(mm) |

76 |

65 |

50 |

|

Rotation |

42r/min |

42r/min |

35r/min |

|

Max. aggregate Dia ( mm ) |

15mm |

12 |

10 |

|

Max. Suct.Left ( m ) |

5 |

5 |

5 |

|

Motor Power (kw) |

18.5kw |

11 |

7.5 |

Manual moulds

The mould size

600x200x200mm

600x200x150mm

600x200x100mm

600x200x75mm

500x400x100mm

500x250x200mm

500x250x100mm

Also could be customized according to your demands

Payment Terms︰ T/T/LC/DP/DA/IN CASH

Packing︰ contained in a 40 feet container

Lead Time︰ Within 7 days after received the prepayment

Standards Certificate︰ ISO9001 CE